This service is a real-time measurement method, which uses physical testing for the application engineer to inspect surfaces in customer items to create enginnering reports and compare results against nominal 2D drawing &3D CAD models.

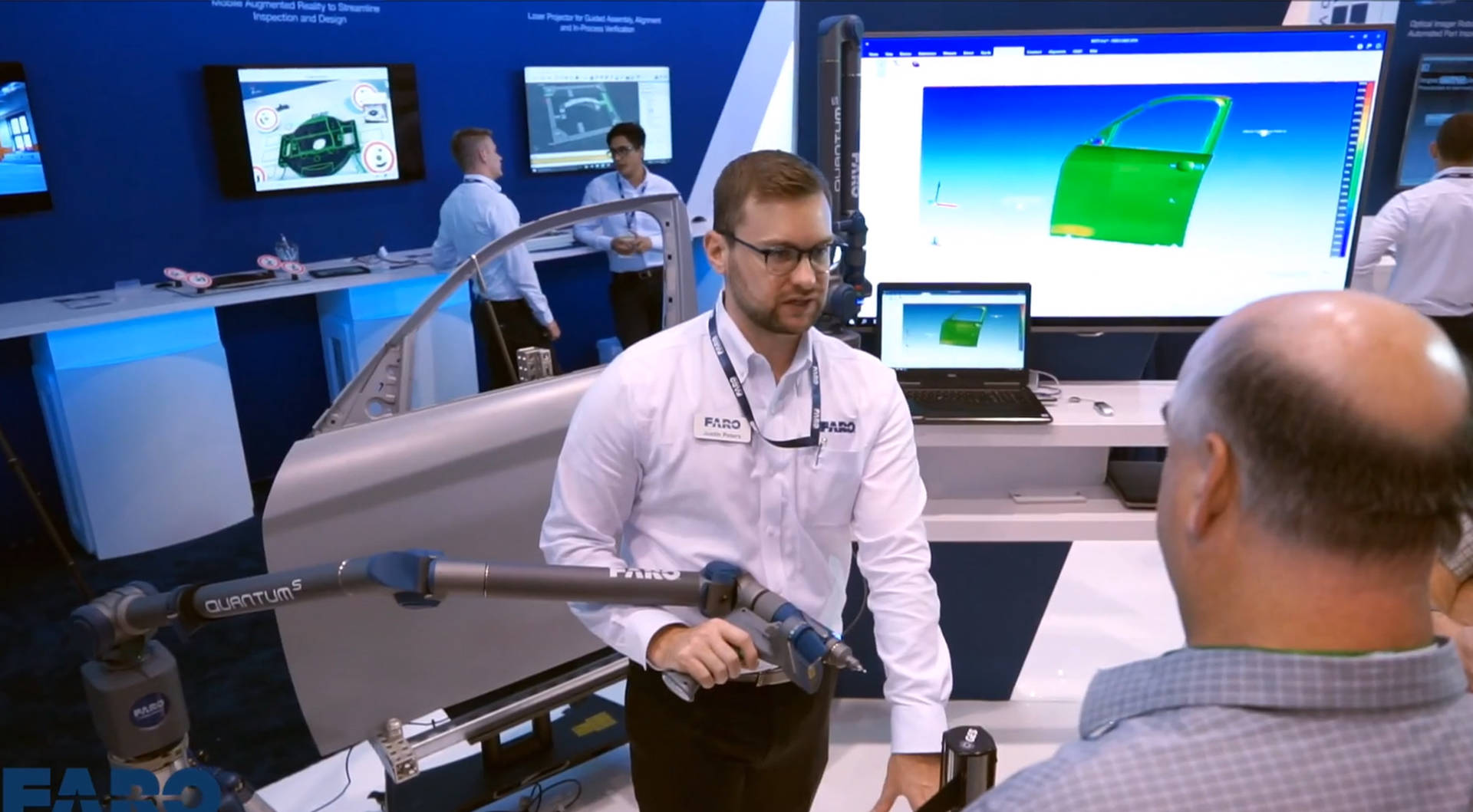

With the latest generation of FARO ScanArm equipment, we offer a fast and efficient method to inspect complex parts and surfaces and capture a point cloud which is compared to your 3D CAD model to complete dimensional analysis.

ScanArm FARO is used to generate a point cloud of an specific item, the geometric features are digitized by scanning (non-contact) to complete a parametric modeling and generate a 3D CAD file. In addition, if required by the client, the 2D drawings of the project are generated.

When inspecting large parts with high volume and weight is required, it can be measured with the FARO Laser Tracker. The equipment has the capacity to support applications of leveling and alignment of machinery & production lines.

Due to its high precision and portability, it can be used for on-site machining inspections for several kind of industries.

The FARO TrackArm is the most versatile portable 3D measurement system, combining the latest advances in FARO 3D measurement technology to offer flexible, easy to use and high accuracy solution for your most demanding 3D measurement needs. The system combines the long range & high precision capabilities of the FARO Laser Tracker with the flexibility and consistency of the FAROArm or ScanArm.

Our engineers are qualified to provide technical support for the use of FARO equipment.